The most important factor in silicone moulds: hardness

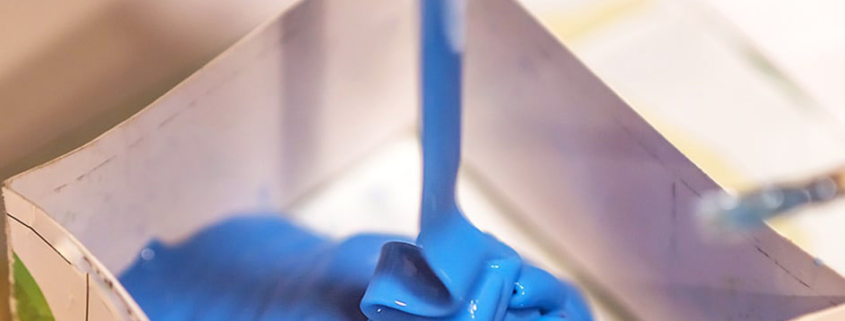

silicone rubber. You can buy it at your local distributor. Silicone rubber is a soft substance that can harden very quickly and is then extremely elastic. However, silicone is not infinitely pliable: if the material is overstretched, it can easily break or crack. The degree of hardness determines the brittleness of the material.

Silicone rubber is available in various hardnesses. The hardness of silicone rubber is expressed in terms of Shore hardness. The rule of thumb here is: the lower the Shore value, the higher the elasticity.

Shore 0 to 20: a soft material with a very high degree of flexibility. However, this material is also relatively unstable.

Shore 20 to 40: A dimensionally stable material with medium elasticity.

Shore 40 to 80: This material is very hard and almost inelastic. It is very dimensionally stable, but also somewhat brittle.

The hardness you should choose for your project depends on what you want to do with silicone. You may also find it easier to use one hardness than another. You’ll just have to try it out.

Basically, the advantage of soft silicone is that you can easily remove the finished piece from the mould after it has hardened. However, the shape is also very unstable and deforms relatively quickly at low hardnesses. In this respect, silicone moulds with high Shore values are of course more difficult to handle, as the castings are not so easy to remove. Furthermore, care must be taken that they do not break or tear during the release process. However, if handled carefully, they can be used regularly because of their high dimensional stability. This is because they do not actually deform at all.

In addition to the level of hardness, the viscosity of the silicone also has an impact on the choice. Depending on the project, you can choose between thick or thin silicone rubber.

If you want to use silicone for chocolate or baking moulds, you must ensure that the material used is food-safe and heat-resistant. A heat resistance of up to 200°C should be given.

If you want to use epoxy, concrete or other chemical casting materials, you should first make sure that the silicone you are using is resistant to chemicals. If you are unsure whether your silicone meets your requirements, read the manufacturer’s data sheet or contact your distributor for advice.

Xiamen Sunshine Technology Co., Ltd. are selling to our global partners, with superior quality, competitive prices and fast delivery.

Choose us as your long-term partner.

For more information, please visit our website http://www.sunshinesi.com.

Sales inquiries can be sent to [email protected]

Leave a Reply

Want to join the discussion?Feel free to contribute!